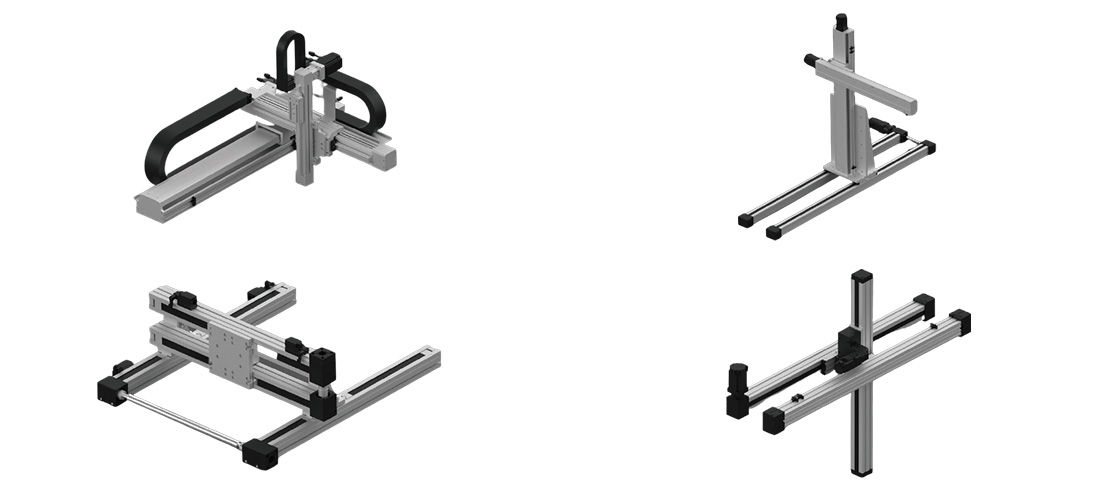

Key considerations for building a multi-axis system include:

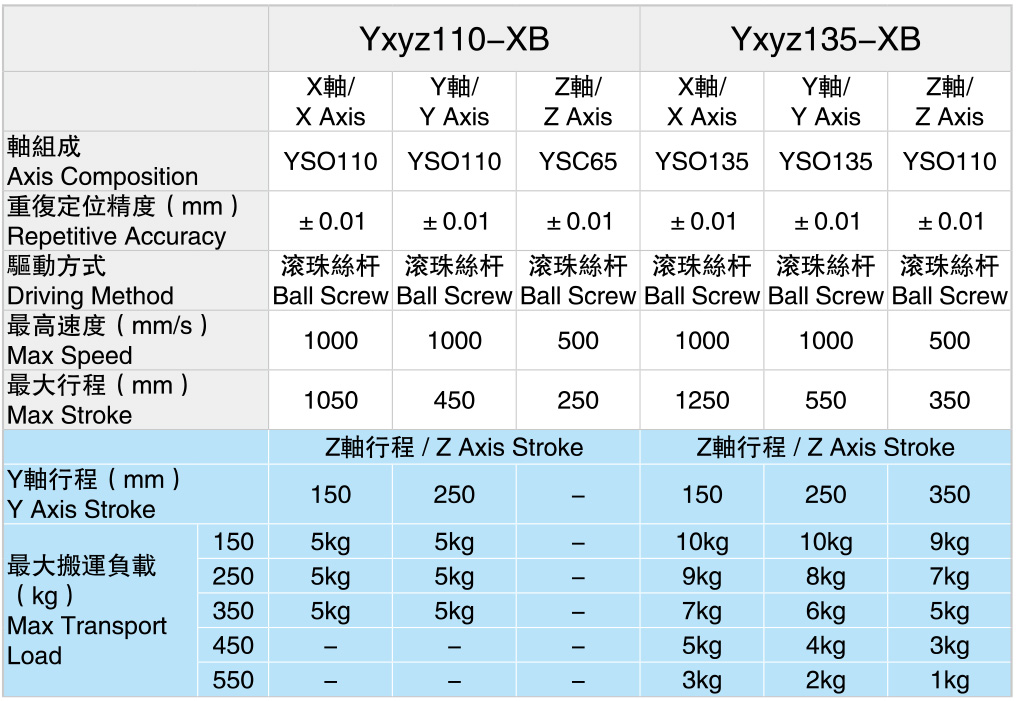

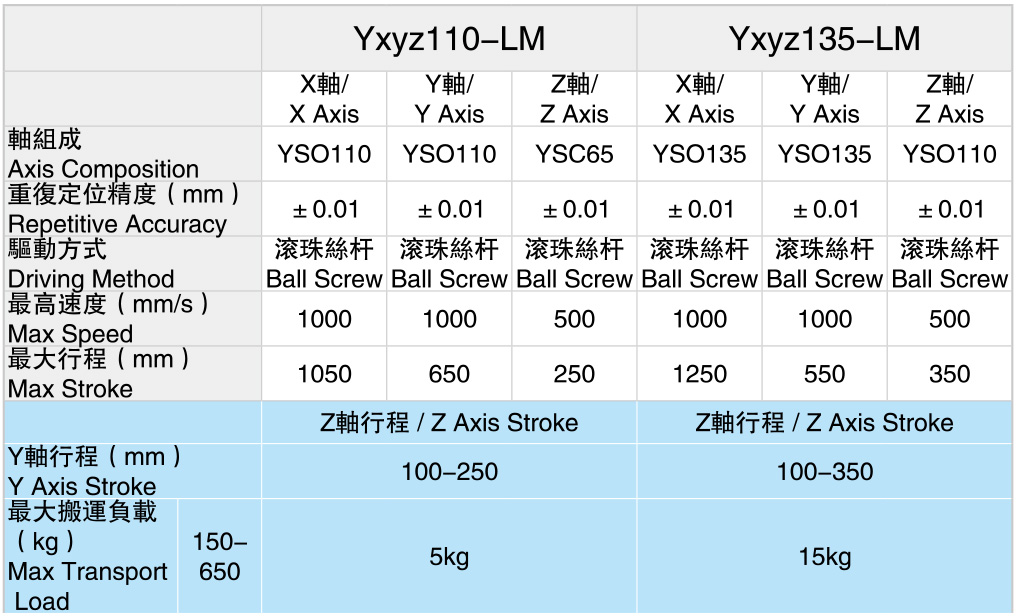

- Load and speed requirements– Ensure that your system can handle the necessary loads while maintaining the desired speed and accuracy.

- Precision and repeatability– For critical applications, ensure the linear units and actuators offer the required precision and repeatability.

- Environmental conditions– Design the system to withstand factors like temperature fluctuations, humidity, or dust, depending on the environment where it will operate.

- Installation direction of the axis– Horizontal/Vertical/Lateral/Upside down.

Ultimately, a well-designed multi-axis system can enhance automation processes, improve production efficiency, and provide long-term reliability.

How SHAC technical team design a multi-axis system for your application?

Designing a multi-axis system requires careful consideration of the specific needs of the application.

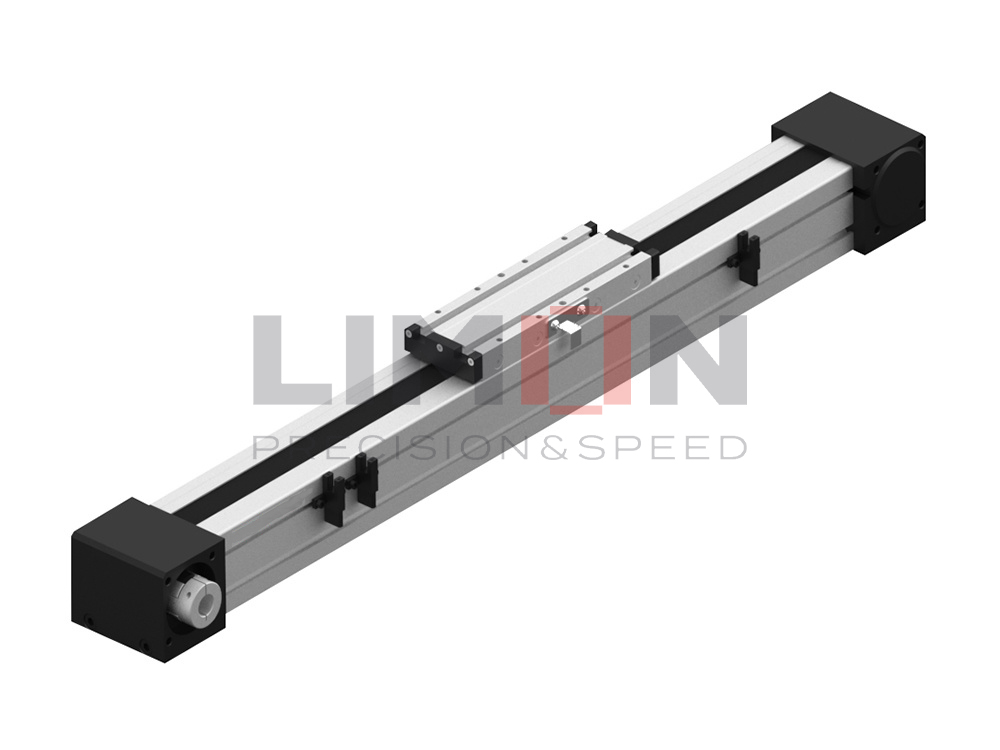

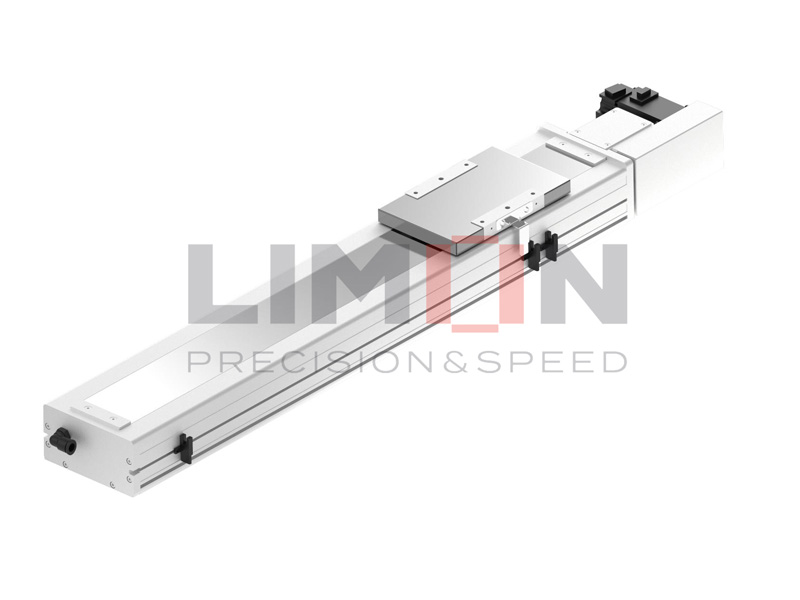

First, identify the motion requirements such as speed, load capacity, and precision. Choose the appropriate linear units to meet these criteria, considering factors like size, stroke length, and mounting options.

Additionally, selecting the right actuators, such as stepper motors or servo motors, is essential for precise control. The integration of these components into a cohesive system will ensure the desired performance.

The design also involves selecting a compatible control system that can coordinate the movement of the axes. When combining multiple axes, ensure that the system’s mechanical and electrical components are well-matched to prevent potential issues like interference or insufficient power. By carefully evaluating the application’s needs and selecting high-quality, reliable components, you can create an efficient and effective multi-axis system.

In addition, the scalability of the system should be considered if future expansions or upgrades are anticipated. Whether you require a 2-axis or a complex multi-axis configuration, ensuring that each component is customizable to your needs is crucial for long-term system performance and flexibility.

Muti-axis system can be used in almost all industries.The breadth of our range makes it possible to find the optimum solution for most applications imaginable. If the standard range is not enough, SHAC is happy to discuss a custom solution that meets your needs. Feel free to contact us!