Using the wrong bearing material can cause rapid wear, premature failure, and costly downtime. Choosing the right material ensures performance, durability, and reliability in demanding applications.

Bearings are manufactured from a variety of materials, including metals, non-metals, and porous metals, each offering unique mechanical properties, wear resistance, and application-specific advantages. Selecting the right one is critical.

Let’s explore the most common bearing materials and their ideal uses.

Metal Materials

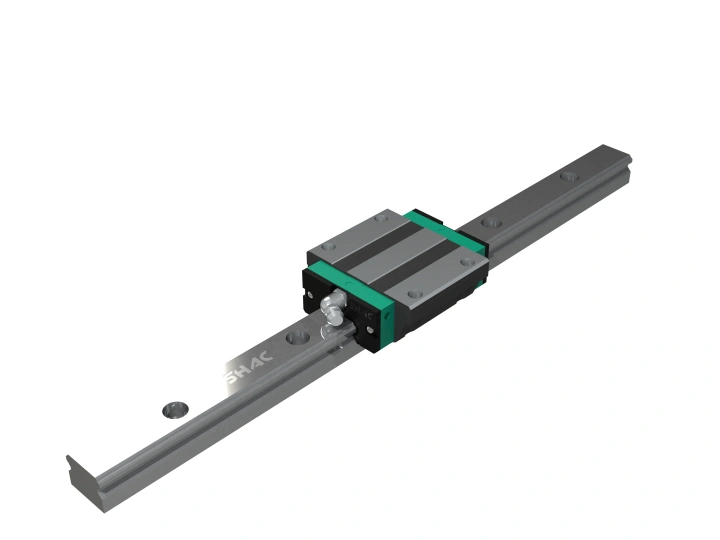

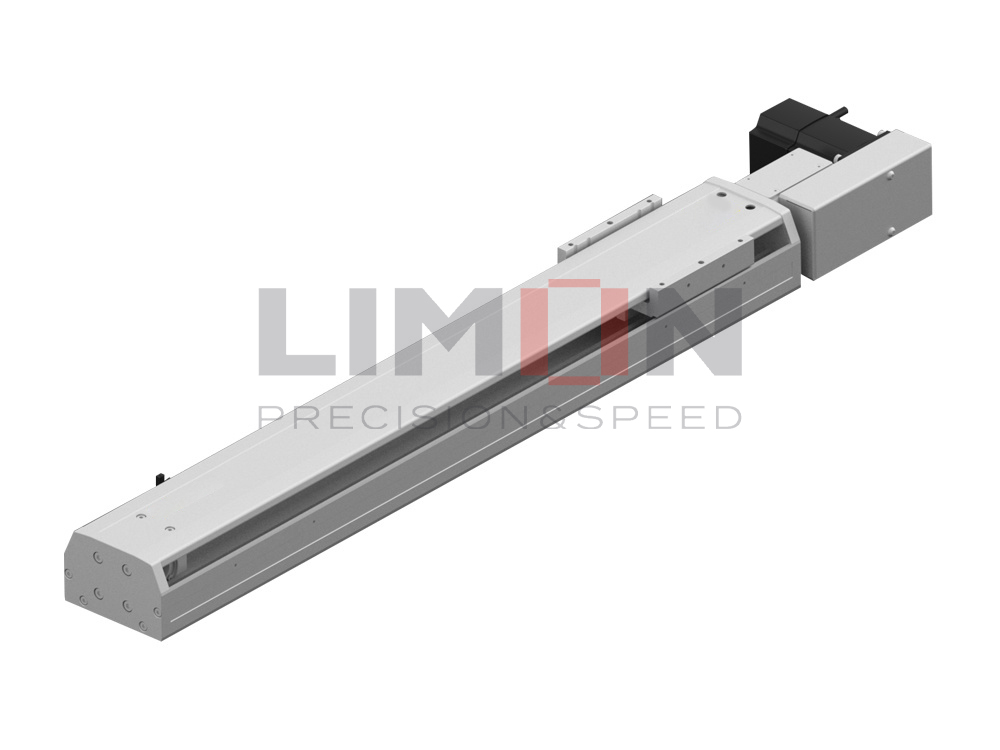

Metal materials dominate bearing manufacturing due to their superior load-bearing capacity, thermal resistance, and precision machinability. Among metals, bearing steels such as SAE 52100 and chrome steel are widely used for high-load, high-speed applications. These steels undergo through-hardening and precision grinding to deliver smooth rolling motion and extended lifespan.

Stainless steel bearings offer the added benefit of corrosion resistance, making them suitable for food processing, medical equipment, and marine applications. Grades like AISI 440C provide excellent hardness and wear resistance while withstanding exposure to moisture or chemicals.

For heavy-duty and extreme environments, bronze bearings (often made from tin bronze or aluminum bronze) provide excellent wear resistance, good load capacity, and superior performance in dirty or abrasive conditions. They are commonly used in industrial machinery where lubrication may be inconsistent.

In high-temperature operations, tool steels or special alloys such as Inconel are used, ensuring dimensional stability under heat. Metals, however, require proper lubrication to prevent friction damage and corrosion.

Non-Metal Materials

Non-metal materials are chosen for applications where weight reduction, chemical resistance, and noise reduction are priorities. Engineering plastics such as PTFE (polytetrafluoroethylene), PEEK (polyether ether ketone), and nylon are popular choices. They offer self-lubricating properties, low friction, and resistance to many aggressive chemicals.

Ceramic bearings, particularly those made from silicon nitride (Si3N4) or zirconia (ZrO2), are favored in high-speed and high-precision environments. Their hardness exceeds most metals, and they perform exceptionally well without lubrication. Ceramic bearings also exhibit excellent corrosion resistance and minimal thermal expansion.

In electrical applications, polymer-based bearings provide electrical insulation while maintaining good wear resistance. These materials are common in electronics manufacturing equipment, where even small static discharges can damage components.

Although non-metal bearings often have lower load capacities compared to metals, they excel in lightweight, corrosion-prone, or cleanroom environments.

Porous Metal Materials

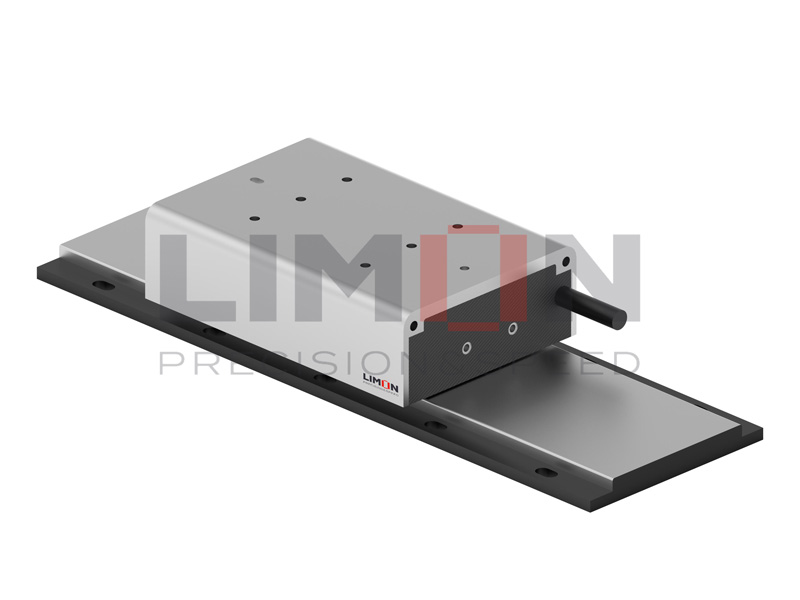

Porous metal bearings combine the strength of metals with self-lubricating capabilities. Typically made from sintered bronze or sintered iron, these bearings are impregnated with lubricants during manufacturing. The microscopic pores in the material store oil, which is released during operation through capillary action.

Sintered bronze bearings are widely used in applications requiring low maintenance, such as home appliances, small electric motors, and agricultural machinery. They operate silently, reduce friction, and eliminate the need for frequent manual lubrication.

Sintered iron bearings are more robust and are preferred in applications where higher loads are expected. They still retain the self-lubricating property but have greater mechanical strength than bronze.

Porous metals are ideal for environments where lubrication intervals are long or where re-lubrication is impractical. However, their performance can degrade if contaminants clog the pores or if they operate in very high-speed conditions without sufficient cooling.

Bearing Material Comparison Table

| Material Type | Advantages | Disadvantages | Common Applications |

|---|---|---|---|

| Metal (Steel, Bronze, Stainless) | High load capacity, wear resistance, long lifespan, heat tolerance | Requires lubrication, can corrode without coating | Automotive, heavy machinery, marine equipment |

| Non-Metal (Ceramic, Plastic, Polymer) | Lightweight, corrosion-resistant, self-lubricating, chemical resistance | Lower load capacity, higher cost for ceramics | Food processing, medical devices, electronics |

| Porous Metal (Sintered Bronze/Iron) | Self-lubricating, low maintenance, quiet operation | Limited high-speed capability, sensitive to contamination | Home appliances, small motors, agricultural machinery |

Conclusion

Selecting the right bearing material ensures optimal performance, longevity, and application-specific suitability.For further questions please contact sales@SHAC.com